Fleet management is essential for the success of any business that operates a fleet of vehicles. Effectively managing fleets can help to ensure that maintenance and repair costs are kept to a minimum. This article will discuss various strategies for managing the maintenance and repair costs of a fleet, such as preventative maintenance, using quality parts and materials, and monitoring vehicle performance. Additionally, it will provide guidance on how to choose the best service providers for repairs and maintenance operations.

The cost of maintaining and repairing a fleet of vehicles can have a major impact on the overall profitability of a business. Therefore, it is important for businesses to implement effective strategies in order to minimize these costs. Preventative maintenance is one of the most important steps for reducing the long-term costs associated with fleet repairs. By proactively inspecting vehicles and addressing potential issues before they become major problems, businesses can save money by avoiding costly repairs down the line.

Using quality parts and materials is also an important factor when it comes to controlling maintenance costs in a fleet operation. The use of poor quality parts or materials can result in components failing more quickly than expected, leading to higher repair costs over time. Additionally, monitoring vehicle performance can help identify areas where repairs may be needed before significant damage occurs; this allows businesses to address issues before they become more expensive problems.

Definition Of Fleet Maintenance & Repair Costs

Fleet maintenance and repair costs refer to the expenses incurred from servicing, maintaining, and repairing vehicles in a fleet. This includes labor costs, parts, and other related expenses such as oil changes or replacement of tires. The goal of effective fleet management is to ensure each vehicle is properly serviced and maintained so that it can run safely, reliably, and cost-effectively.

The maintenance needs of a fleet vary depending on the size and type of vehicles used. For instance, large fleets with heavy-duty trucks require more frequent servicing than fleets with smaller cars. Additionally, some fleets may require specific maintenance tasks such as diesel engine tuning due to their unique characteristics. As such, it is important for fleet managers to be aware of the different types of maintenance requirements for their vehicles in order to effectively manage their costs.

To reduce the overall cost associated with maintaining and repairing a fleet, proactive measures should be taken to minimize the need for repairs or service visits. This can include regular inspections of vehicles to identify potential problems before they become costly repairs. Additionally, preventive maintenance is important in order to keep vehicles running efficiently and extending their life span which can ultimately save money in the long run.

Establishing A Budget For Maintenance & Repair Costs

Creating a budget for fleet maintenance and repair costs is essential for managing them effectively. A good starting point is to assess the current cost of maintenance and repair. This information can be obtained from reviewing invoices, work orders, and other documents related to past repairs. Additionally, estimates from mechanics or vendors should also be considered when assessing maintenance costs. Once a budget has been established, it is important to review it regularly and adjust it as needed based on the actual costs incurred.

It is also important to plan for potential future expenses when establishing a budget. For example, some vehicles may require more expensive repairs such as brakes or transmission replacement. It is essential to take into account these possible expenses when developing the budget so that they do not come as an unexpected expense later on. Additionally, parts prices may fluctuate over time due to inflation or other economic factors and it should be taken into consideration when structuring a budget.

Fleet managers should also investigate options for discounts or special offers in order to reduce costs associated with maintenance and repair expenses. Many vendors offer discounts for bulk purchases or loyalty rewards programs which can help manage overall costs better. Furthermore, preventive maintenance can save money in the long run by reducing the need for major repairs and extending vehicle life expectancy. Being mindful of these strategies can ensure that fleets remain operational while minimizing overall maintenance cost expenditures.

Techniques For Controlling And Reducing Costs

Effective fleet management requires proactive maintenance and repair strategies to ensure the safe and efficient operation of vehicles. There are several techniques that can be utilized to control and reduce costs related to fleet maintenance and repair. First, preventative maintenance is essential in maintaining the health of a fleet to avoid costly repairs. Regular checks of vehicle systems, such as brakes, fluids, tires, and batteries can help identify potential issues before they become costly problems. Additionally, keeping up with regularly scheduled services like oil changes or tune-ups can extend the lifespan of a vehicle and reduce future expenses.

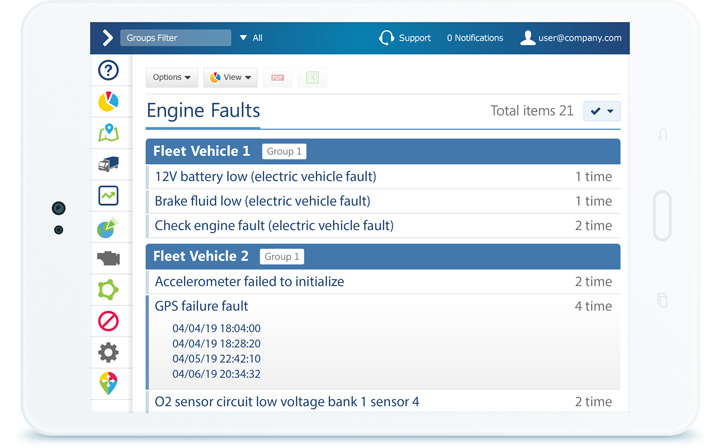

Second, tracking data on repairs and service history can provide valuable insight into where money is being spent on each vehicle. Keeping an organized record of past repairs and preventive maintenance checklists allows fleets managers to identify recurring issues that may go unnoticed otherwise. This information can also be used to negotiate better pricing when dealing with outside vendors.

Finally, investing in quality parts for repairs can save money in the long run by avoiding unnecessary repeat visits due to faulty components or substandard materials. Purchasing parts from reliable suppliers who include warranties on their products should be a priority for fleets looking to reduce future repair costs. By utilizing these techniques for controlling and reducing maintenance costs, fleets can optimize their spending while ensuring the safety of their drivers and vehicles.

Benefits Of Proactive Fleet Management

Proactive fleet management offers several benefits that can contribute to reducing maintenance and repair costs. By anticipating and addressing issues before they become more serious, proactive fleet managers can save time and money in the long run. Regular inspections are an essential part of proactive fleet management, allowing for the identification and resolution of any problems before they become too costly. This type of preventative maintenance helps to ensure the safety and reliability of vehicles while also helping to reduce repair costs.

In addition, proactive fleet management facilitates better communication between mechanics and technicians. This allows for a more efficient troubleshooting process, as well as more accurate diagnoses that reduce unnecessary repairs or replacements. As a result, time is saved by avoiding potential delays due to inaccurate information or faulty parts being used in repairs. Furthermore, proactive fleet management encourages collaboration between technicians, which can help identify solutions that may not have been considered prior to a problem arising.

Proactive fleet management also allows for better tracking of vehicle performance over time, enabling managers to be aware of any potential issues before they arise. By collecting data such as engine performance and fuel efficiency levels over regular intervals, managers can be alerted when there is an abnormality that requires further investigation or repair work. This approach helps companies plan ahead for future repairs and anticipate unexpected expenses that may arise if left unmanaged. Overall, proactive fleet management offers considerable value by helping companies save money on maintenance and repair costs while ensuring the safety and reliability of their vehicles.

Adopting Automated Solutions

Automated solutions are an attractive option for fleet managers looking to better manage their maintenance and repair costs. By automating the process of tracking, scheduling and completing repairs, fleet managers can streamline the management of costs while ensuring that vehicles are maintained in optimal condition. Automated solutions also allow fleet managers to leverage data to improve forecasting, scheduling and cost control. With automated solutions, fleet managers can track real-time data such as fuel consumption, mileage and repair records that can help optimize workflow and minimize out-of-pocket expenses.

Automated solutions also reduce manual labor associated with maintaining fleets by providing a centralized platform for tracking all relevant information. This allows the manager to quickly identify potential problems or areas in need of attention. Automation also helps ensure that preventive maintenance is scheduled on time so that costly repairs are avoided or minimized. Finally, automated systems can provide timely reminders of upcoming scheduled maintenance so that it is not overlooked or forgotten.

By adopting automated solutions, fleet managers have the opportunity to reduce their overall maintenance and repair costs while improving safety and vehicle performance. Automated systems allow for greater efficiency in tracking repairs, parts and other essential components, thereby allowing fleet managers to better understand their overall expenses over time. Moreover, automation helps ensure that preventive maintenance is properly scheduled in order to avoid costly repairs down the road. As a result, these tools may prove invaluable for any fleet manager looking to effectively manage their maintenance and repair costs.

Frequently Asked Questions

What Is The Best Way To Monitor A Fleet’s Maintenance And Repair Costs?

Monitoring maintenance and repair costs for a fleet is an essential part of effective management. The cost of repairs and maintenance can quickly add up, so it is important to monitor the expenditure regularly to ensure that it remains within budget. There are a variety of methods available for tracking fleet maintenance and repair costs, including software programs, manual tracking methods, and other digital tools.

Software programs provide one of the most efficient ways to track fleet maintenance and repair costs. These programs are designed to simplify the task by providing users with an automated system for logging expenses and generating reports on expenditures over time. Software programs may also offer additional features such as reminders when maintenance or repairs are due or alerts when budget limits have been exceeded. Additionally, many software programs provide detailed analytics which can be used to identify areas where money could be saved through better planning or more efficient processes.

Manual tracking methods also provide a viable option for monitoring fleet maintenance and repair costs. Manual tracking involves keeping paper records of expenses such as invoices and receipts in order to track spending over time. This method allows users to easily review their spending history and make adjustments accordingly, though it may require more effort than using software programs due to the need for manual data entry. Other digital tools such as spreadsheets may also be used in combination with manual tracking methods in order to create comprehensive records that can easily be updated as new expenses occur.

When choosing a method for monitoring fleet maintenance and repair costs, it is important to consider both budget limitations and any specific needs that must be met in order to effectively manage the fleet’s expenses. By understanding the available options and selecting the best solution based on current needs, businesses can ensure they remain within budget while ensuring their fleets remain operational at all times.

What Is The Most Cost-Effective Way To Maintain A Fleet?

Maintaining a fleet of vehicles is an important part of any business that operates a fleet. The cost associated with maintaining these vehicles can have a significant impact on the overall profitability of the organization, which makes it essential to have an effective and cost-efficient maintenance strategy in place. As such, it is important to understand what is the most cost-effective way to maintain a fleet.

There are several methods available for managing and monitoring the maintenance costs of a fleet. One approach is to create a system for tracking maintenance costs at each stage of the vehicle life cycle. This system should include regular inspections and preventive maintenance performed according to manufacturer guidelines, as well as tracking repair costs for each individual vehicle in order to identify any potential issues before they become more costly problems. Additionally, it is important to keep accurate records of all services and repairs performed in order to monitor how much money has been spent on maintaining each vehicle over its lifetime.

Another approach for reducing maintenance costs involves using technology-based solutions such as telematics systems or fuel management systems. These systems can provide real-time data about the performance and condition of each vehicle, allowing organizations to identify potential issues early and take corrective action before they become larger problems. By taking advantage of these systems, fleets can reduce unplanned downtime, improve efficiency, and ultimately reduce their overall maintenance costs.

In order to ensure that fleets remain cost-effective, it is important for businesses to develop comprehensive strategies for managing their fleet’s maintenance and repair costs. This includes regularly inspecting vehicles and performing preventive maintenance according to manufacturer guidelines, tracking repair costs across all vehicles in order to identify potential issues early on, and utilizing technology-based solutions such as telematics systems or fuel management systems in order to optimize operations and reduce unplanned downtime or other costly issues.

Are There Any Tax Implications When Managing A Fleet’s Maintenance And Repair Costs?

When managing a fleet’s maintenance and repair costs, there are important tax implications that need to be taken into consideration. As an owner or operator of a fleet, it is essential to understand how taxes on these expenses can impact the overall budget. Different types of taxes may apply depending on the type of vehicle and its operations, as well as any other services that may be used for maintenance and repair.

The first type of tax is typically levied on fuel purchases. This tax can vary from state to state, but it is typically calculated based on the amount of fuel purchased. Additionally, in some states special taxes may be applicable to certain types of vehicles, such as commercial trucks or buses. Other taxes may include registration fees, sales tax and property tax on vehicles owned by the fleet, or other services related to the operation of a fleet.

Finally, owners should also consider potential deductions when filing taxes related to their fleets’ maintenance and repair costs. Depending on the size of the business, certain expenses may be deductible in order to reduce taxable income. Some examples include repairs that are necessary for safety reasons or parts that have been replaced due to excessive wear and tear. It is important for owners to review their specific situation with a qualified accountant in order to determine what deductions may be available for their fleets’ expenses.

In summary, when managing a fleet’s maintenance and repair costs, it is important for owners to consider various types of taxes that may apply as well as potential deductions that could reduce taxable income. With careful planning and professional advice from an accountant familiar with this area, owners can ensure they are making informed decisions regarding their fleets’ financial health.

What Kind Of Training Do I Need To Effectively Manage A Fleet’s Maintenance And Repair Costs?

When managing a fleet’s maintenance and repair costs, it is important to ensure that the team responsible has adequate training and resources. To ensure success in this area, appropriate training should be provided to those in charge of managing the fleet. This training should include an understanding of the various components of a vehicle, as well as how to identify potential problems before they arise. Additionally, the training should cover topics such as budgeting for maintenance and repair costs, vendor selection and negotiation, and risk management.

In addition to providing adequate training for those involved with maintaining and repairing fleet vehicles, there are other measures that can be taken to effectively manage these expenses. Developing a preventive maintenance plan can help identify potential issues before they occur and reduce overall expenses associated with repairs. It is also important to establish clear guidelines for when repairs are needed and who is authorized to make them. Establishing policies regarding preventative maintenance will also help reduce costs over time.

Finally, having access to reliable data can assist in making informed decisions when it comes to managing a fleet’s maintenance and repair costs. Utilizing data such as cost estimates on parts or services, trends in usage or mileage, breakdowns or service history, can all provide valuable insight into which areas need attention or improvement. With access to accurate data, managers can better anticipate any future expenses associated with maintaining their fleets’ vehicles.

Is There Any Software Available To Help Manage A Fleet’s Maintenance And Repair Costs?

The proper management of a fleet’s maintenance and repair costs is essential for any business. There have been technological advancements in recent years that have enabled companies to better manage these costs. One such advancement is the use of software to help manage these costs. This article will discuss the advantages and disadvantages of using such software and the importance of training when using it.

Software can be an effective tool to help manage a fleet’s maintenance and repair costs, as it can provide businesses with detailed records of all expenses related to repairs and maintenance. Additionally, this software can also help identify areas where more efficient usage of resources can be made, which helps reduce overall costs associated with running a fleet. By knowing exactly where money is being spent, businesses are able to better allocate their funds towards other important areas.

However, there are potential drawbacks associated with using software for managing maintenance and repair costs as well. For example, if the user does not have adequate training in how to use the software properly, they may experience difficulty understanding how to navigate its features or inputting the correct data into it. Furthermore, there may be additional fees associated with purchasing and maintaining the software itself, which could offset any savings incurred from its usage.

It is therefore important for companies utilizing such software for managing their fleets to ensure that their staff are adequately trained in how to use it properly, in order to maximize its potential benefits while avoiding any possible pitfalls. In addition, businesses should consider all factors associated with purchasing such software before making a decision on whether or not it is right for them.

Conclusion

The effective management of a fleet’s maintenance and repair costs is essential for the success of any business. It requires a combination of implementing the right strategies, using the most cost-effective methods, understanding the related taxes, properly training personnel, and utilizing available software. By taking into account all these aspects, businesses will be able to optimize their fleets’ maintenance and repair costs while still ensuring that their vehicles are in optimal working condition.

Businesses must take into consideration all factors when managing a fleet’s maintenance and repair costs. This includes understanding the tax implications associated with such expenses as well as properly training personnel on how to handle them. Additionally, businesses should use software to keep track of their fleets’ maintenance and repair costs in order to make informed decisions about future expenses.

In conclusion, effectively managing a fleet’s maintenance and repair costs is essential for any business in order to ensure that they remain competitive while also minimizing expenses associated with vehicle upkeep. Businesses must understand the relevant taxes related to such costs as well as properly train personnel on how to manage them. Furthermore, utilizing available software can help businesses make informed decisions about future repairs and maintenance expenses in order to optimize their fleets’ performance.